Introduction

In the rapidly evolving aerospace industry, integrating Extended Reality (XR) technologies is crucial for design, training, maintenance, safety, and operational efficiency. For startups, XR offers a competitive edge, streamlines processes, and boosts productivity. Building an XR team involves strategic talent acquisition, technology selection, and workflow integration to fully leverage XR’s potential, fostering innovation and collaboration within the aerospace sector’s rigorous standards and dynamic environment.

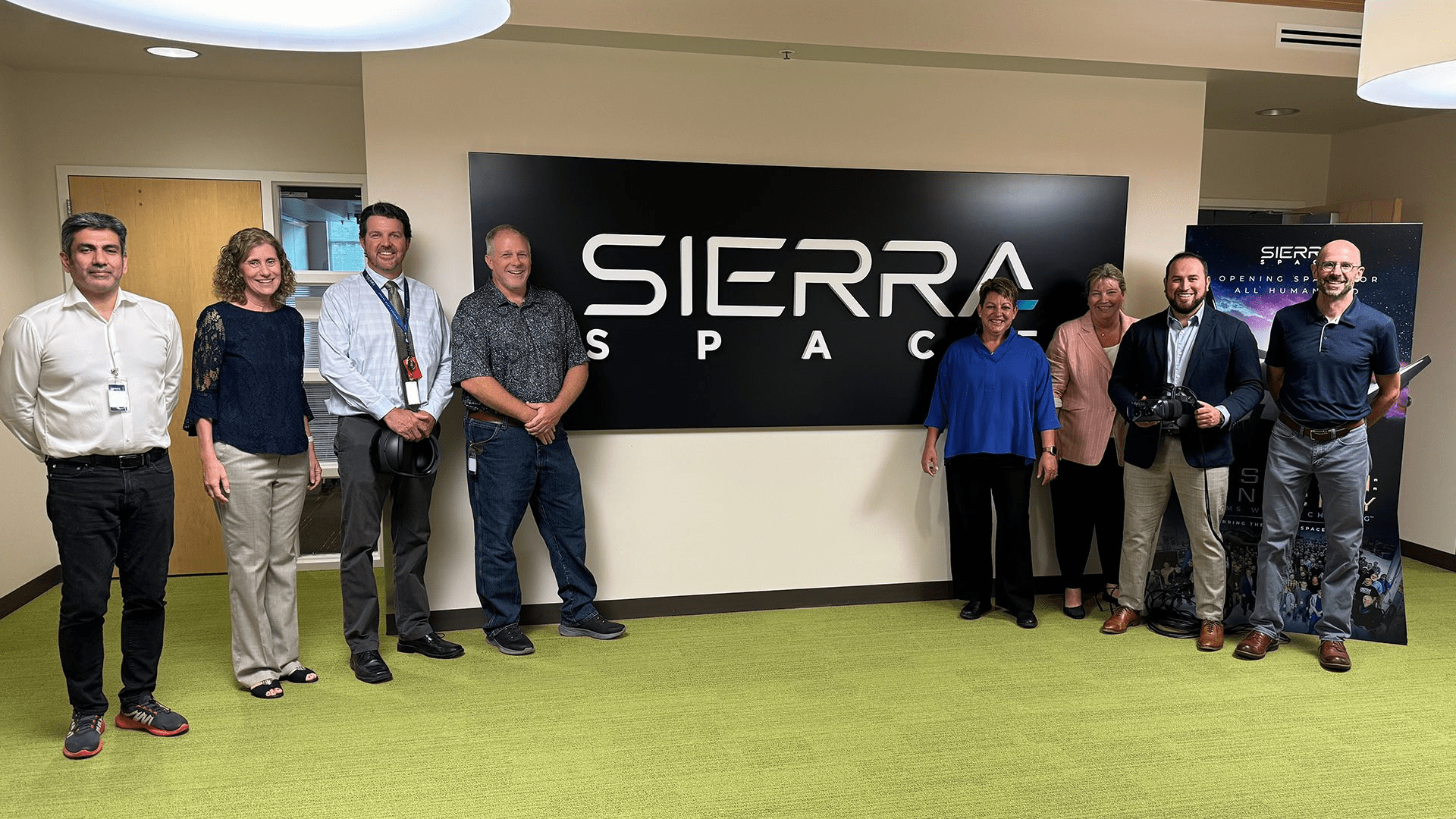

In this blog, we cover Tim Ventura’s (iQ3Connect) interview with Alejandro Mendoza from Sierra Space and Bridgette Sieffert from Terran Orbital Corporation. They discuss essential factors for building a strong XR team in aerospace startups, such as identifying the right talent, setting clear objectives, and implementing advanced tools while fostering ongoing learning. This blog provides a comprehensive roadmap for creating a team that drives XR initiatives and propels your startup to new heights. Click here to watch a recording of the full conversation.

The value XR brings to the aerospace/small satellite industry

More and more digital models of products, production equipment, and manufacturing facilities are being generated to assist manufacturing and industrial companies for various reasons. Some companies do it to make faster and more informed decisions, some to bring products to market quicker, and others to stay competitive in this global economy. Let us see how AR can add value to Aerospace startups:

- Excitement and Motivation: Using a headset that offers a holistic virtual experience excites trainees with new technology, unlike traditional paper and pencil methods, which made tracking progress challenging.

- Ease of Use: AR simplifies manufacturing procedures, such as designing and building satellites, by eliminating the need to refer to 2D drawings on a computer screen. Technicians have all the necessary information directly in front of them, including wire connections, torque specifications, and screw order, enhancing efficiency and accuracy. This reduces errors and ensures high-quality work from the early stage.

- Business Development: AR simulations provide customers with immersive tours, showcasing technological advancements and the ability to improve product quality. This impressive demonstration creates a strong impact, boosting customer engagement and satisfaction.

“When we have customer tours come in we actually show them different AR simulations that our technicians use and say hey that is how we are implementing this is really cool technology this is how we are making advances and how we can build your product better. And, they loved that. It’s definitely a big wow factor on the tours for them” – Bridgette Sieffert

At the business level, proving the new technology’s value to investors involves showcasing its application on the manufacturing floor, where complex assemblies like fighter jets are constructed. Demonstrating its benefits includes meeting with investors and presenting the technology’s maturity and manufacturability.

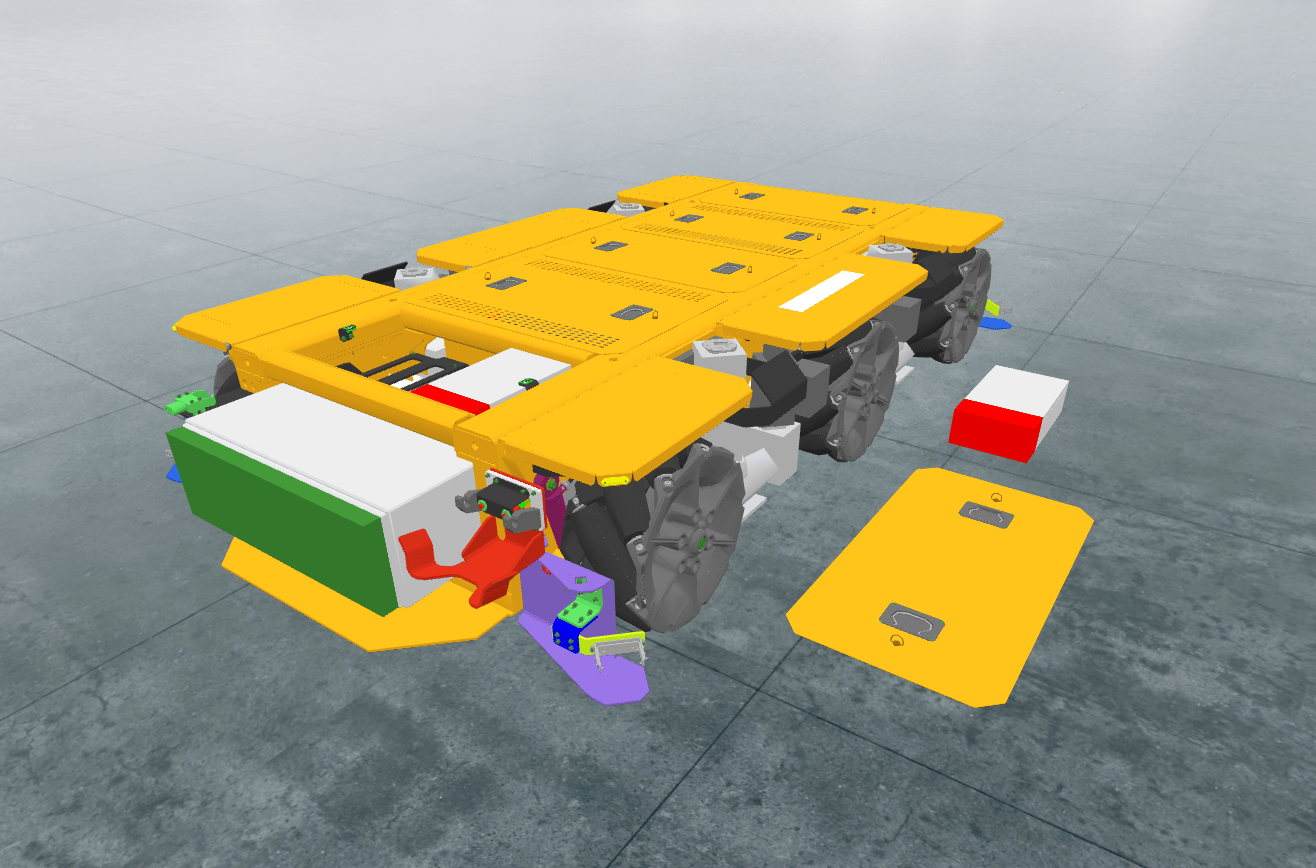

Transitioning from training sessions to investor demonstrations highlights the design’s maturity. Showing how the technology is implemented in manufacturing and inspection, such as deconstructing a satellite down to its smallest component and showcasing other minute details, captures investor attention and proves the technology’s practical benefits. Alejandro outlined one of the creative ways that XR is being used within the organization.

“Meeting with investors demonstrating the maturity of our designs, and also the ways that we were implementing the technology with design for manufacturability or inspection. Quite literally piecing apart the satellite piece by piece down to the ball bearing. That definitely caught the eye of a lot of different people as we went through multiple pitch phases. Holistically (we) went from training to demonstration to investors”– Alejandro Mendoza

Overcoming IT hurdles

In the ever-evolving landscape of IT and security, overcoming challenges often requires innovative thinking and adaptive strategies. Addressing these issues involves not only traditional solutions but also creative approaches tailored to the unique needs of the environment.

“Everyone wants you to succeed, even those who are opposing you because it’s their job. It’s their job to keep our assets and our nation safe.” – Alejandro Mendoza

In the complex world of aerospace projects, especially projects under stringent government contracts, IT professionals face the challenge of managing on-premises solutions due to security concerns, and avoiding cloud applications. Overcoming this challenge involves presenting clear business cases that highlight the value proposition of on-prem solutions, thereby reducing the need for extensive research and fostering excitement among IT teams. Building strong relationships with IT departments can facilitate this transition, making the case for on-prem solutions more compelling and manageable.

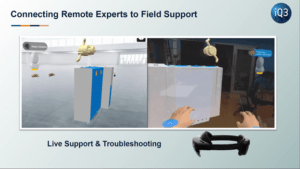

Similarly, cybersecurity professionals often find themselves unfamiliar with advanced visualization technologies. To bridge this gap, involving knowledgeable volunteers who can demonstrate the vulnerabilities and potential of technologies like AR can be highly effective. Allowing IT professionals to experience these technologies firsthand through headsets and visualizations not only showcases their practical applications but also generates enthusiasm and a collaborative spirit within the team.

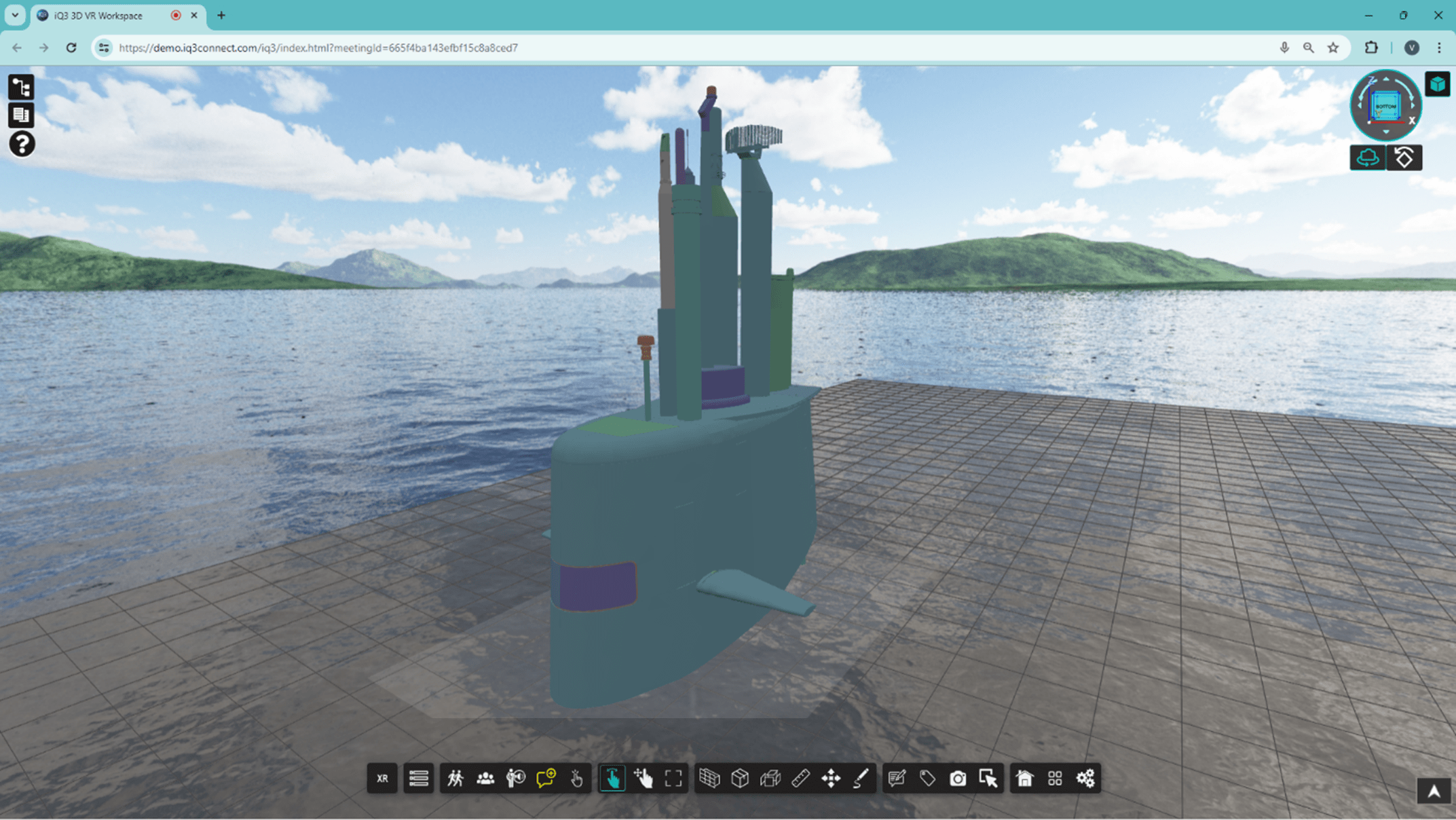

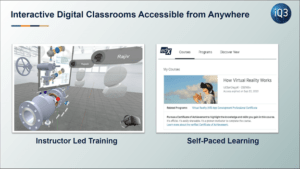

iQ3Connect is one of the only web-based XR platforms solely focused on the manufacturing and industrial market needs. Being a web-based XR platform means that all a user needs is access to a standard web browser on any device. For IT that means that users can access content on their existing (already approved) devices, experiences are deployed on standard web browsers that are already supported, and there are no apps or software for individual users to download/IT to manage.

Management, technology, and team engagement

One of the biggest challenges at the outset of a project is securing and appropriately allocating funds for critical initiatives. This can be effectively addressed by approaching the company’s finances with the same care and responsibility as if they were your own, crafting pitches that emphasize ROI, and aligning your request with the priorities of program directors and executive leadership.

“I am not trying to sell you a pie-in-the-sky idea, it’s something that can be measured and returned calculated” – Alejandro Mendoza

Presenting a clear business case that includes a detailed timeline, predicted ROI, and resource requirements, combined with transparency across all levels from the shop floor to the C-suite can expedite the funding process and facilitate project approval.

“What’s worked for me has been a business case. Coming to management with here’s our timeline, our predicted ROI, and the resources I’m going to need.” – Bridgette Sieffert

For team engagement, exposure to new technologies can rapidly ignite innovative ideas, as demonstrated when mechanical teams use headsets to explore potential use cases. This hands-on experience not only excites the team but also generates creative solutions, highlighting the importance of having a presence on the shop floor. Engaging with engineers, technicians, and managers directly allows for the collection of valuable insights and ideas, opening up numerous opportunities for application.

Managing expectations and finding scalable solutions are crucial in this process. When presenting to management, the team should communicate that while custom development was initially necessary, using existing assets enables quicker turnarounds and more efficient resource use, showcasing both innovation and practicality.

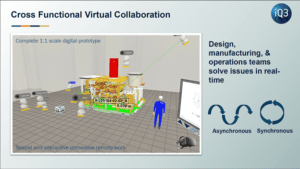

The use of AR technology can lead to successful projects due to its cross-functional benefits. For instance, a 3D floating model of a satellite can be utilized by the design team, and mechanical engineers for reviews, and mission operations for spatial visualization. Leveraging corporate resources allows for broader application across different groups, garnering more support through multiple use cases.

To receive buy-in from all levels, customers need to be able to use existing resources to create content rapidly. iQ3Connect has focused development efforts in this area and earlier this year we released the newest version of our no-code authoring environment for XR training. The iQ3Connect platform is minimizing the buy-in hurdle by expanding the pool of potential personnel capable of authoring content (no CAD, XR, or graphic design experience required), optimizing content creation workflows (automated CAD to XR pipeline), and employing a cost-effective and scalable licensing structure (unlimited content creators and guests).

Roll out, adoption, and reception of XR across an organization

One of the biggest learning opportunities is generating excitement about using the headset- a new technology many haven’t tried. Presenting it in an appealing way helps technicians see its benefits.

Utilizing, engaging and teaching strategies makes the technology easier to use, as people are unlikely to embrace something they find uncomfortable or confusing.

When designing the rollout plan, it’s crucial to consider diverse age groups, from tech-savvy younger users to seasoned experts less familiar with rapid tech evolution. Creating a plan that effectively supports all age groups ensures a smooth introduction and broad acceptance.

Device selection and safety considerations

Ensuring safety in manufacturing requires technicians to be comfortable with headsets. Standardizing headset use on the shop floor can streamline training, as using a consistent lens reduces the need for extensive retraining when switching devices. Key features to consider include augmented reality support, ease of use, and compatibility with all systems. When addressing capability factors such as hardware and software compatibility with MR, it’s crucial to have a clear method and rationale for investing in various headsets.

Conclusion

The integration of XR technologies in aerospace startups offers transformative benefits, from enhancing design and training to improving operational efficiency. Insights from Tim Ventura’s interview with Alejandro Mendoza and Bridgette Sieffert underscore the importance of strategic talent acquisition, clear goal setting, and effective implementation of advanced tools. Emphasizing AR’s value in creating immersive customer experiences, showcasing practical applications to investors, and addressing IT and cybersecurity challenges are crucial for success. By fostering innovation and collaboration while managing expectations and leveraging existing resources, aerospace startups can drive XR initiatives that elevate their capabilities and propel them to new heights. For a deeper dive into the conversation, be sure to check out the full video recording.