The realm of Extended Reality (XR) has always been synonymous with headsets and hardware. But what if we told you that the future might not require you to don those bulky goggles? In this post, we’ll explore the feasibility of experiencing XR without the headset, the technologies making it possible, and what this means for the future of XR.

The Evolution of XR Technology

When XR first entered the public consciousness, it was almost entirely dependent on headsets. These devices, often cumbersome and expensive, were the gatekeepers to immersive virtual worlds. While the experience was groundbreaking, it was also limiting, tethering users to specific hardware. But as technology evolves, so does the way we interact with XR. The question now is, can we experience XR without the need for a headset?

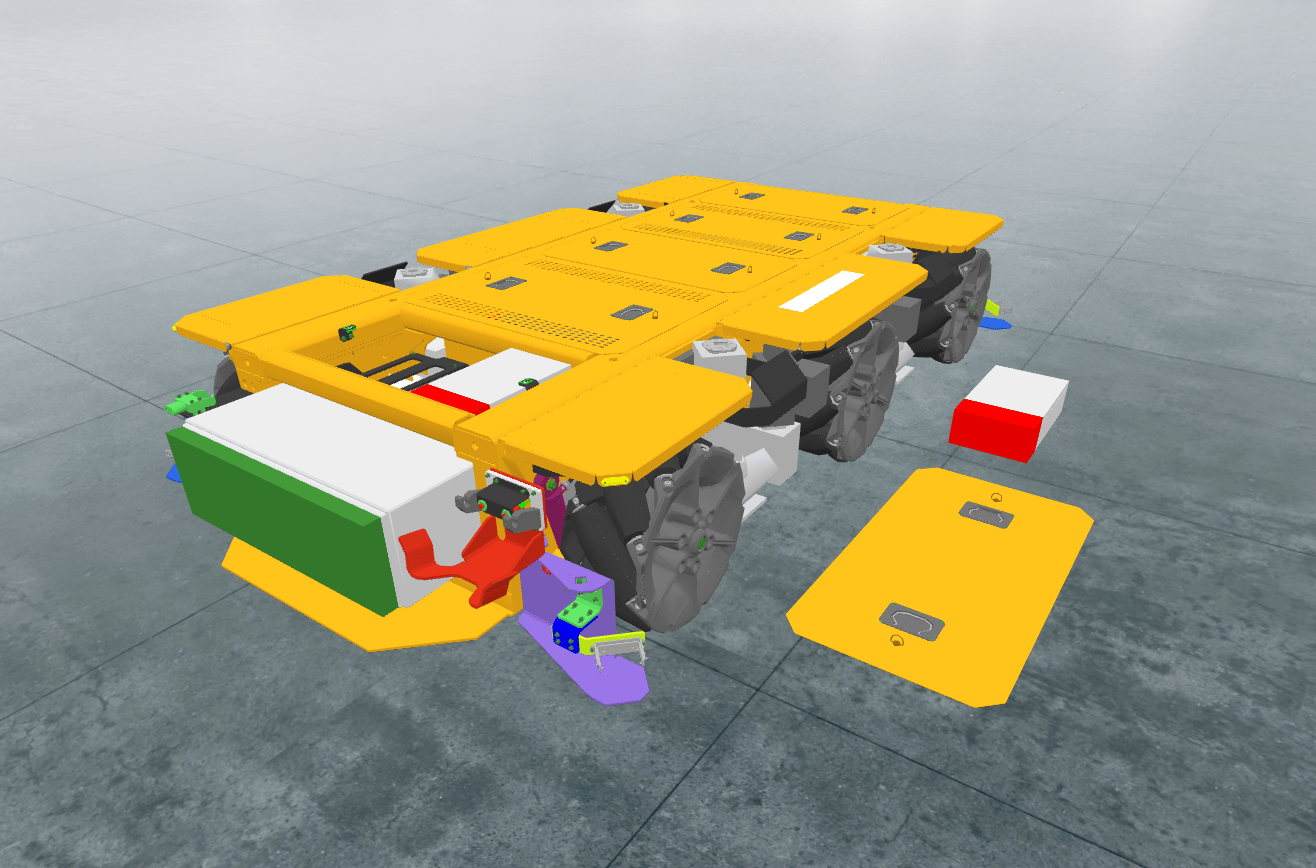

Over the last few months, we worked on some intriguing research with our brilliant AI/ML intern, Zain Raza, who just completed his undergraduate degree at MakeSchool. The objective of the research project was to investigate the performance and reliability of hand and face tracking using a webcam for industrial collaboration and training applications. We aptly named the project “Headsets: Goodbye!” envisioning a future where devices to consume and interact with immersive 3D content will become ubiquitous and no longer exclusively in the domain of headsets.

Why did we embark on the “Headsets: Goodbye!” Project? Well, remote, real-time collaboration is arguably the most environmentally friendly way to conduct business with globally distributed teams, suppliers, and customers. Even with employees moving back to offices and factories, remote collaboration can undoubtedly minimize latency, cost, and carbon footprint due to the reduction in travel of personnel and equipment. However, we have increasingly seen the negative effects of video-conferencing fatigue, lack of social interactions, and other challenges of working from home.

The Quest for Headset-Free XR

The industry has been buzzing with efforts to make XR more accessible and less hardware-dependent. From projection-based systems to haptic feedback suits, the quest for headset-free XR is more than a pipe dream. However, this journey is fraught with challenges, from technical limitations to user adaptability. Companies are experimenting with various technologies, such as spatial computing and gesture recognition, to make this a reality.

Benefits of Going Headset-Free

Imagine experiencing XR without the discomfort of a headset. Not only does it make the technology more accessible, but it also opens doors to new applications, from education to manufacturing. Studies have shown that headset-free XR can offer a more comfortable and prolonged experience, thereby increasing user engagement. The freedom from hardware could revolutionize how we think about virtual spaces, making them more integrated into our daily lives.

Increased Accessibility

Headsets can be a barrier to entry for many users, both in terms of cost and ease of use. Going headset-free makes XR more accessible to a broader audience, including those who may have physical limitations that make using a headset uncomfortable or impractical.

Cost-Effectiveness

Investing in high-quality XR headsets for each user can be a significant expense for organizations. A headset-free approach can dramatically reduce these costs, making it easier for companies to adopt XR technologies.

Enhanced User Comfort

Wearing a headset for an extended period can lead to discomfort or even motion sickness for some users. The headset-free experience eliminates these issues, allowing users to engage with XR content more comfortably and for longer periods.

Simplified Collaboration

Headsets can sometimes isolate users, making collaborative experiences more challenging to implement effectively. Headset-free XR facilitates easier communication and collaboration among users, whether they are in the same physical space or connecting remotely.

Greater Flexibility

Without the need for a headset, users are free to interact with XR content in a way that suits them best, whether that’s through a desktop, tablet, or even a smartphone. This flexibility can be particularly beneficial in educational settings, where different learners have different needs.

Easy Integration

As Zain points out, going headset-free allows for easier integration into existing systems and processes. This is particularly beneficial for companies that are looking to implement XR solutions without disrupting their current operations.

By addressing these benefits, a headset-free approach to XR not only solves many of the challenges associated with traditional XR but also opens up new avenues for innovation and engagement.

Current Technologies Making Headset-Free XR Possible

Several emerging technologies are pushing the boundaries of what’s possible in headset-free XR. Spatial computing, for instance, allows for a more interactive experience without the need for a headset. Think of it as the difference between watching a 3D movie with glasses and stepping into a holographic room. Other technologies like computer vision are also contributing to this shift, offering new ways to interact with digital information.

Challenges and Solutions

While the prospect of headset-free XR is exciting, it’s not without its challenges. Issues such as motion sickness in projection-based systems and the high cost of haptic suits are barriers to adoption. However, ongoing research and development promise solutions that could make headset-free XR a mainstream reality. Companies like iQ3Connect are at the forefront of this innovation, working to overcome these challenges and make XR more accessible to everyone.

Future Perspectives

As we look to the future, the question isn’t just whether XR can be headset-free, but how soon. With advancements in AI and machine learning, we might soon experience XR in ways we can’t even imagine today. The convergence of various technologies could lead to a more seamless and integrated XR experience, free from the constraints of current hardware.

The journey toward headset-free XR is an exciting but challenging one. While current technologies offer a glimpse into what’s possible, the industry still has hurdles to overcome. However, the potential benefits make this a quest worth pursuing. As technology continues to evolve, the possibilities for headset-free XR are limitless.

To learn more about Zain’s work on Roberto The Empathetic Robot and our project, check out the article linked below: https://Blog.Devgenius.Io/Digital-Avatars-The-Next-Leap-In-Remote-Work-C72c0cd369a7