Transforming Technical Skill Training with AR and VR

The process for technical training has evolved from manual, hands-on processes to the immersive realms of Augmented Reality (AR) and Virtual Reality (VR). Initially, technical skill development was focused on hands-on experience with paper documentation, with attempts to transition to digital mediums with the advent of online technologies. However, these new digital methods fell short in engagement and development, leaving employees lacking critical knowledge and skill sets. AR and VR technologies are addressing this issue by providing what no other digital method could: physically realistic and interactive training.

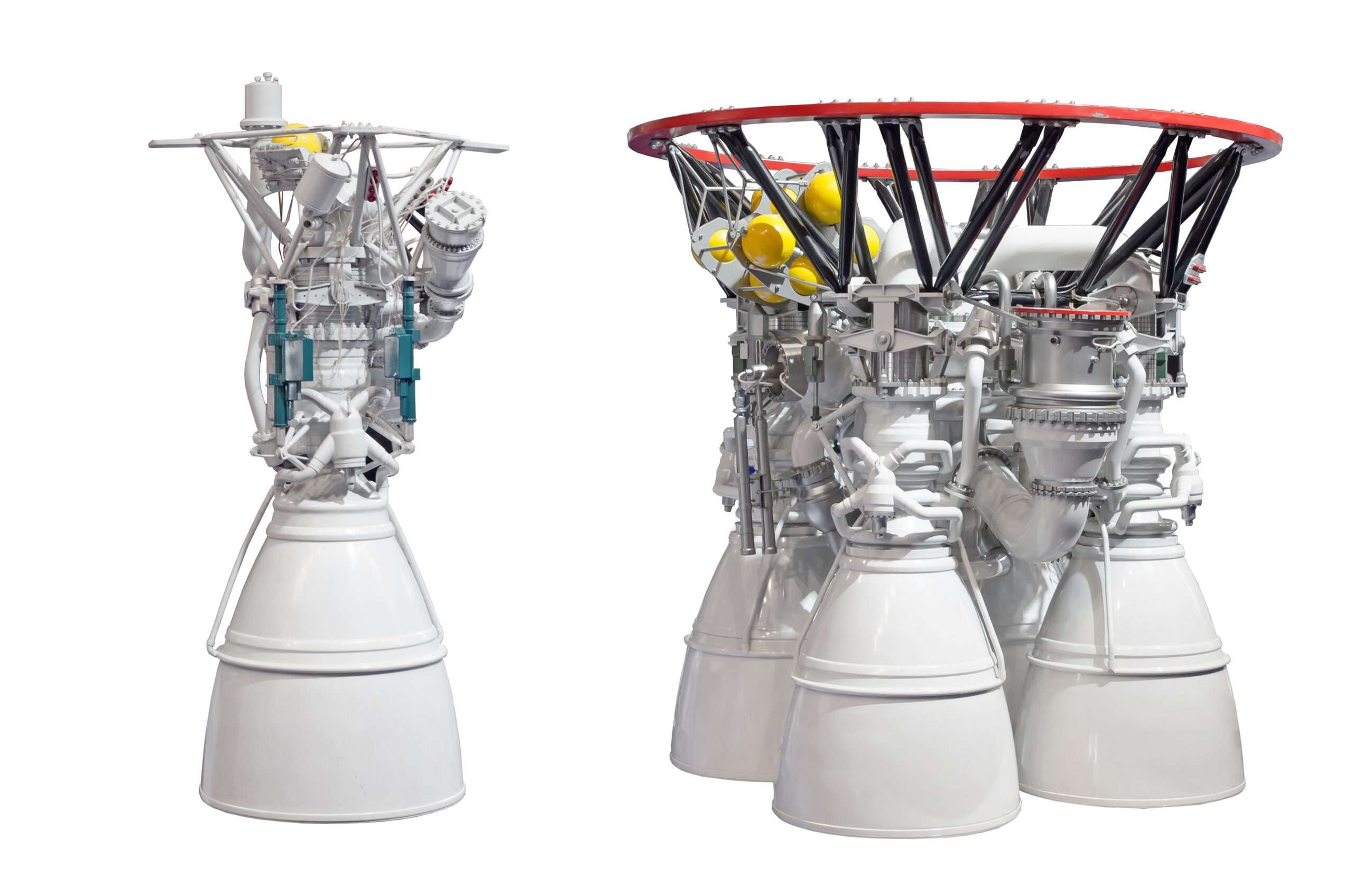

Physical training equipment and models are being replaced by interactive, virtual 3D models, easily viewable on any phone, tablet, PC, or AR or VR headset. AR and VR technologies not only replicate the hands-on training experience, but improve upon it by enabling global remote training and automated feedback and assessments, creating a more effective learning environment.

The transition to AR and VR for technical skill development is a substantial stride towards enhancing the efficiency and effectiveness of workforce training. By addressing the core challenges of traditional hands-on training and the insufficiency of traditional digital methods, AR and VR have not only made the process more engaging but have significantly upgraded the training experience, ensuring that trainees are well-equipped and confident as they step into their new roles.

Common Technical Training Challenges Solved with AR and VR

The traditional technical training process often presents numerous challenges that can hinder efficient workforce development, from facility and equipment requirements, to instructor availability, to travel logistics. AR and VR technologies address these challenges, ensuring a more efficient and engaging training experience. Here’s how AR and VR tackle common technical training challenges:

Use Cases for VR and AR Technical Skills Training

Maintenance and Repair

- Maintenance: train technicians on how to maintain equipment, leveraging AR and VR technology to avoid having to shut down physical equipment.

- Repair: use step-by-step virtual instructions with realistic interactions with a virtual model to train employees on proper repair procedures, including safety procedures such as lockout tagout.

Manufacturing and Assembly

- Manufacturing: train manufacturing personnel on the entire assembly line, allowing them to understand the production process and even quality control and inspection.

- Assembly: virtually assemble products or equipment to train employees on the order of operations, the proper tools to use, and how to use them.

Material Handling and Equipment Operation

- Material Handling: Prepare trainees for proper material handling, including how to operate machinery, store the material, what PPE to wear, and how to handle material spills.

- Equipment Operation: Train employees to operate equipment and heavy machinery, allowing them to train in a virtual environment without risk to themselves or the equipment.

Safety

- Fall Prevention: Train employees on proper fall prevention procedures including the proper use of safety gear and lifting equipment and hazard identification.

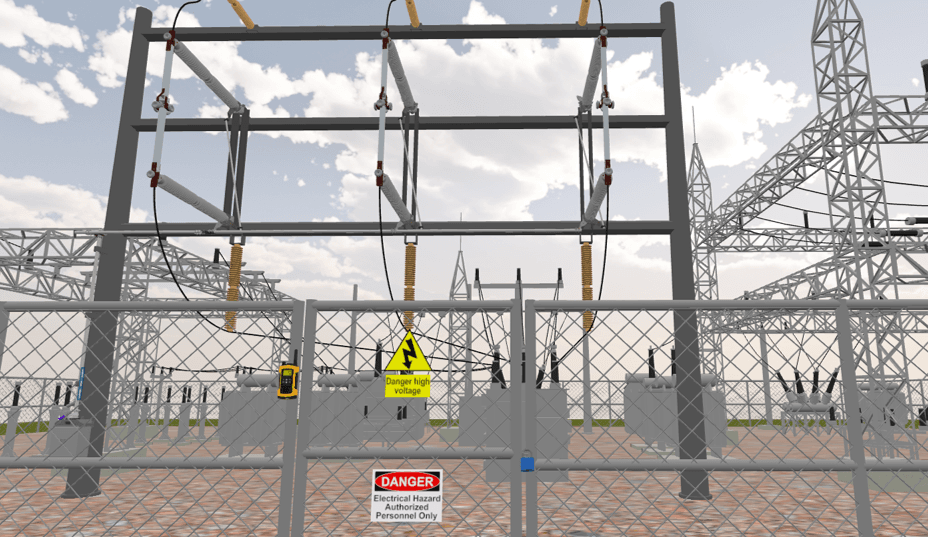

- Electrical Safety: Provide training on electrical safety, including identifying electrical hazards and responding to electrical emergencies.

Skills Assessment

- Performance Evaluation: Use AR and VR technology to assess the technical skill set of new hires pre- and post-training, adapting the training content to meet their specific needs, and continually monitoring training effectiveness.

- Candidate Assessment: provide a realistic, virtual technical skill assessment to verify that the prospective employee is a good fit.

The ROI of AR and VR Technical Skills Training

Leveraging AR and VR technology as part of your program for technical skills training is not only effective but also cost-efficient. Businesses that adopt AR and VR training report significant improvements in training outcomes, a reduction in training costs, and increase in employee retention. The investment in AR and VR technology pays off by creating a more engaged and productive workforce at lower cost, reducing the rate of employee turnover and consequently lowering related expenses such as hiring and training costs.

What Sets iQ3Connect Apart?

iQ3Connect’s platform is designed to empower anyone to cost-effectively build & deploy AR and VR experiences for technical skills training, without programming knowledge or modeling expertise.

Web-Based

No software or application downloads required, ensuring a seamless experience throughout the technical training process, from experience creation to end-user access and performance monitoring. All you need is a web browser.

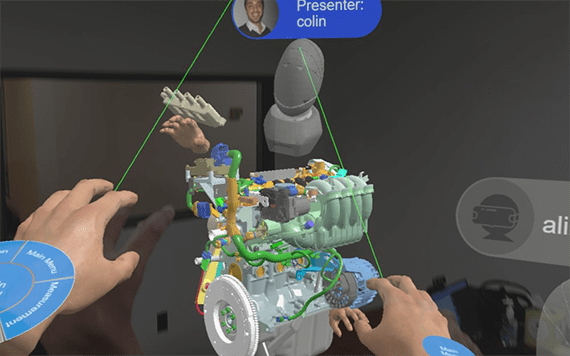

Immersive Collaboration

In addition to single-user, on-demand AR and VR technical skills training, iQ3Connect’s platform supports multi-user, instructor-led training. Transcend geographical barriers and enable real-time remote interactive learning.

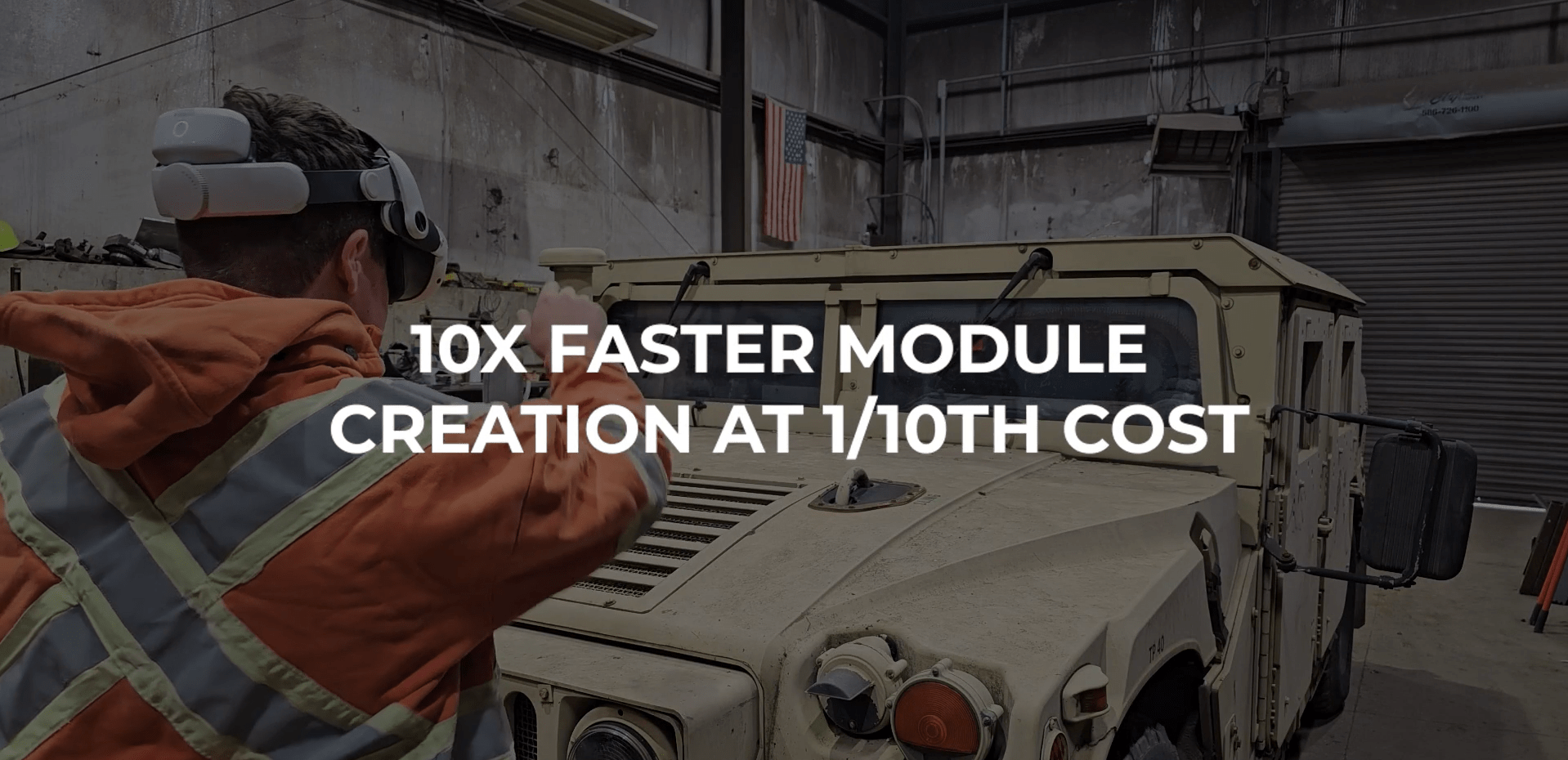

No-Code Authoring Tools

Build AR and VR experiences as easily as a slide deck. Our platform includes no-code authoring tools, empowering your team to create compelling immersive experiences without coding expertise, facilitating a more efficient creation process and enabling rapid customization of training modules.

Access Anywhere, Anytime

Our web-based platform (either on-premise or in the cloud) ensures that the technical skills training is accessible from anywhere, at any time, without sacrificing user or data security. Collaborate with your global team or train at your own pace.

AR and VR Technical Skills Training for Engaged Learning

The key to effective training is engagement and retention, and this is where AR and VR truly excel. By providing realistic, immersive, and interactive experiences, these technologies ensure that the learning process is not only engaging but also deeply impactful. Employees are more likely to remember and apply the lessons learned in an AR/VR setting due to the contextual and hands-on nature of the training. Testimonials from various industries, including manufacturing, automotive, aerospace, and energy, underscore the effectiveness of AR and VR in enhancing learning outcomes and ensuring a more productive workforce.

Trusted By

Indian Aerospace Company

Principal Scientist

C M Venkat

Vice President, Aker Solutions

Mark Lawrence

3D Geospatial Consultant, Waves Group

Dennis (Chip) Herrick

Sr. Information Technologies Specialist, Bosch

Jeffrey Jacobson

XR Project Manager, Boston Children’s Hospital

Joe Strelow

President, AVL Power Systems

BJ Foster

CEO, PRR

Device & Software Compatability

Use Any Device

iQ3Connect prioritizes the accessibility of immersive training, ensuring that even those without an AR or VR device still have access to the critical technical training content. Every training created with our platform can be used with any AR, VR, PC, tablet, or mobile device, ensuring a hassle-free experience for everyone.

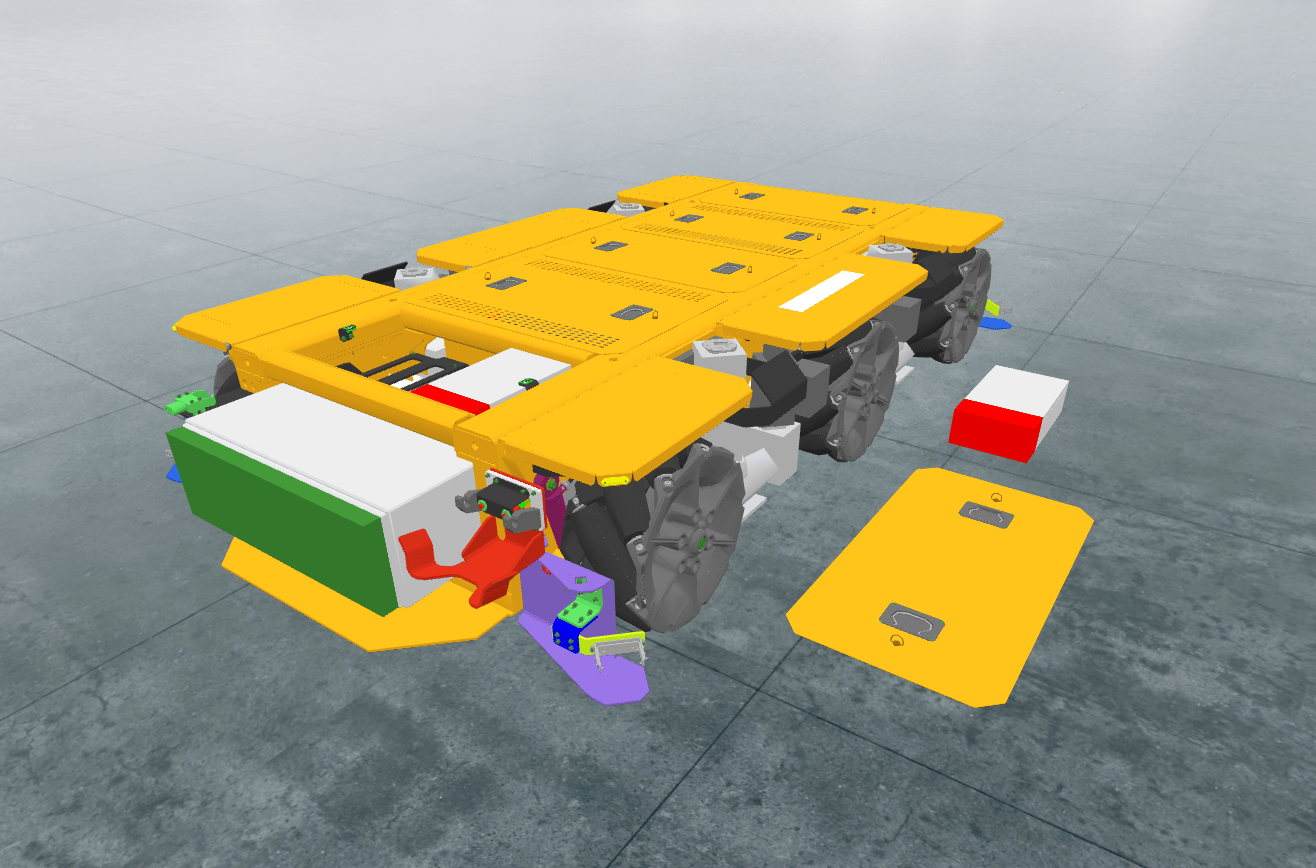

Seamless Content Import

Our platform supports direct import of 3D CAD and point cloud files, eliminating the need for modeling expertise or model simplifications. We not only automate the process but also ensure that the integrity and precision of the original data is maintained without performance deterioration. In addition, 360 videos and images, documents, images, videos, and audio files can all be imported to create training experiences.

Enterprise Integration

Seamlessly integrate AR and VR experiences into your everyday processes. Our platform can connect to single sign-on, learning management systems, access control lists, product lifecycle management tools, and more, ensuring data security and interoperability. Moreover, our open web-based platform makes it easy and cost-effective to integrate into any other business tool or processes.

Ready to revolutionize your technical skills training? Discover the world of possibilities with iQ3Connect’s AR and VR platform.

More Resources

News

iQ3Connect Product Release v2025.2

Read More

Blog

Meta Quest 74.0: Scaling Enterprise XR with Streamlined …

Read More

XR Workspace

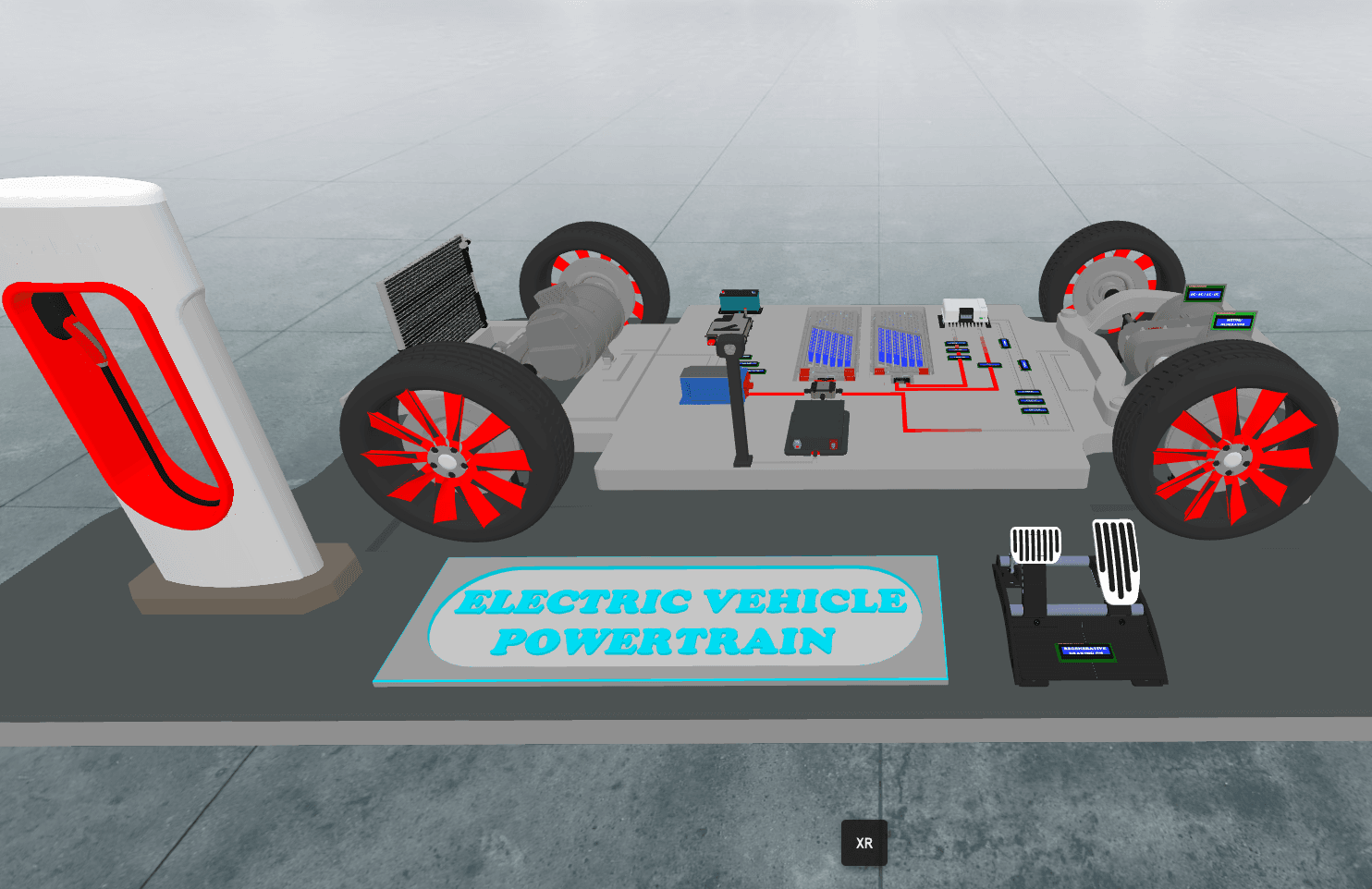

Educational Example – EV Powertrain

View Details

Blog

Quest 3: Boundaryless AR on the Web

Read More

News

iQ3Connect Product Release v2025.1

Read More

XR Workspace

Feature Showcase – Animations and Interactivity

View Details

XR Workspace

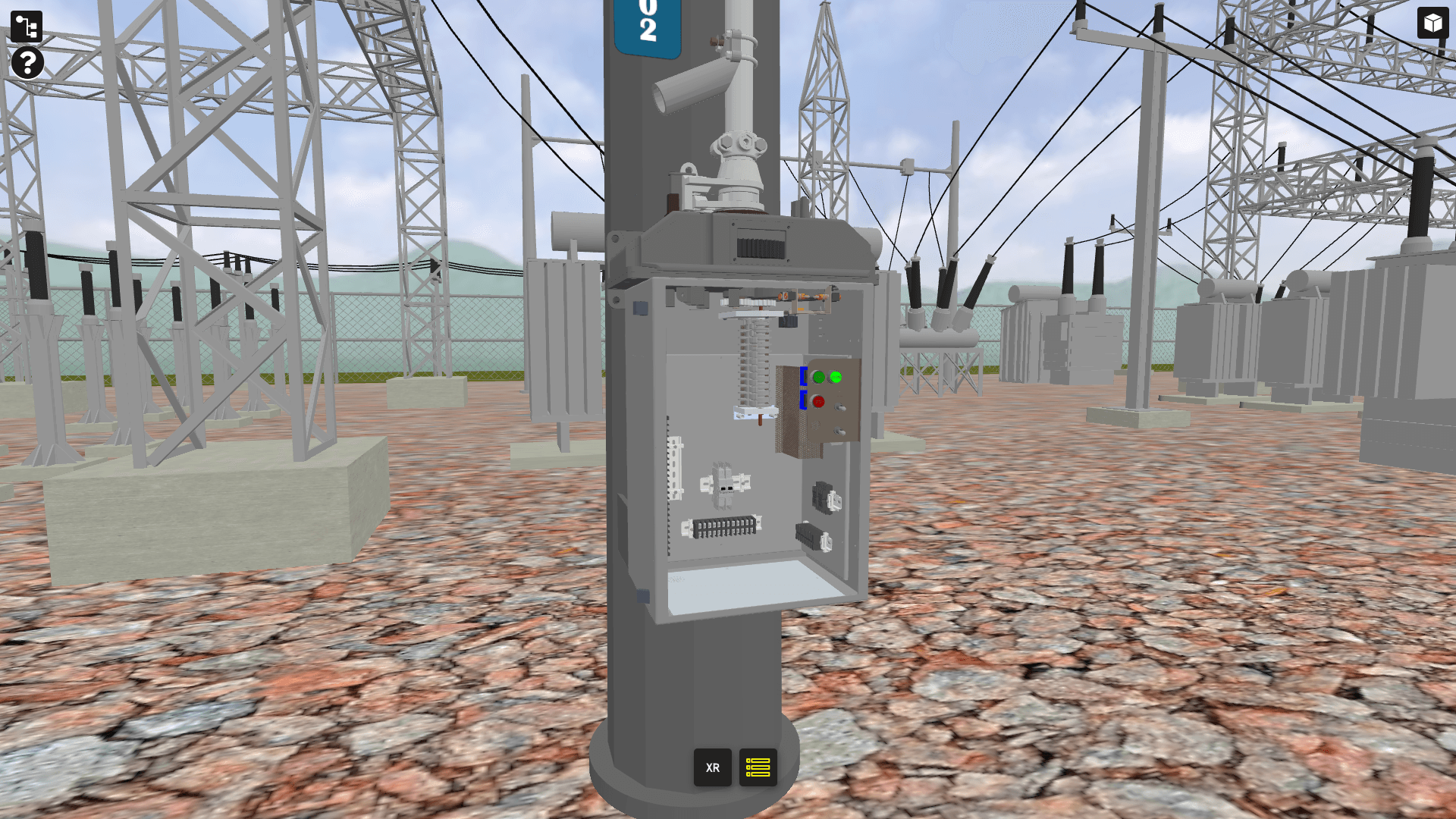

Safety Training – High Voltage Disconnect

View Details

Blog

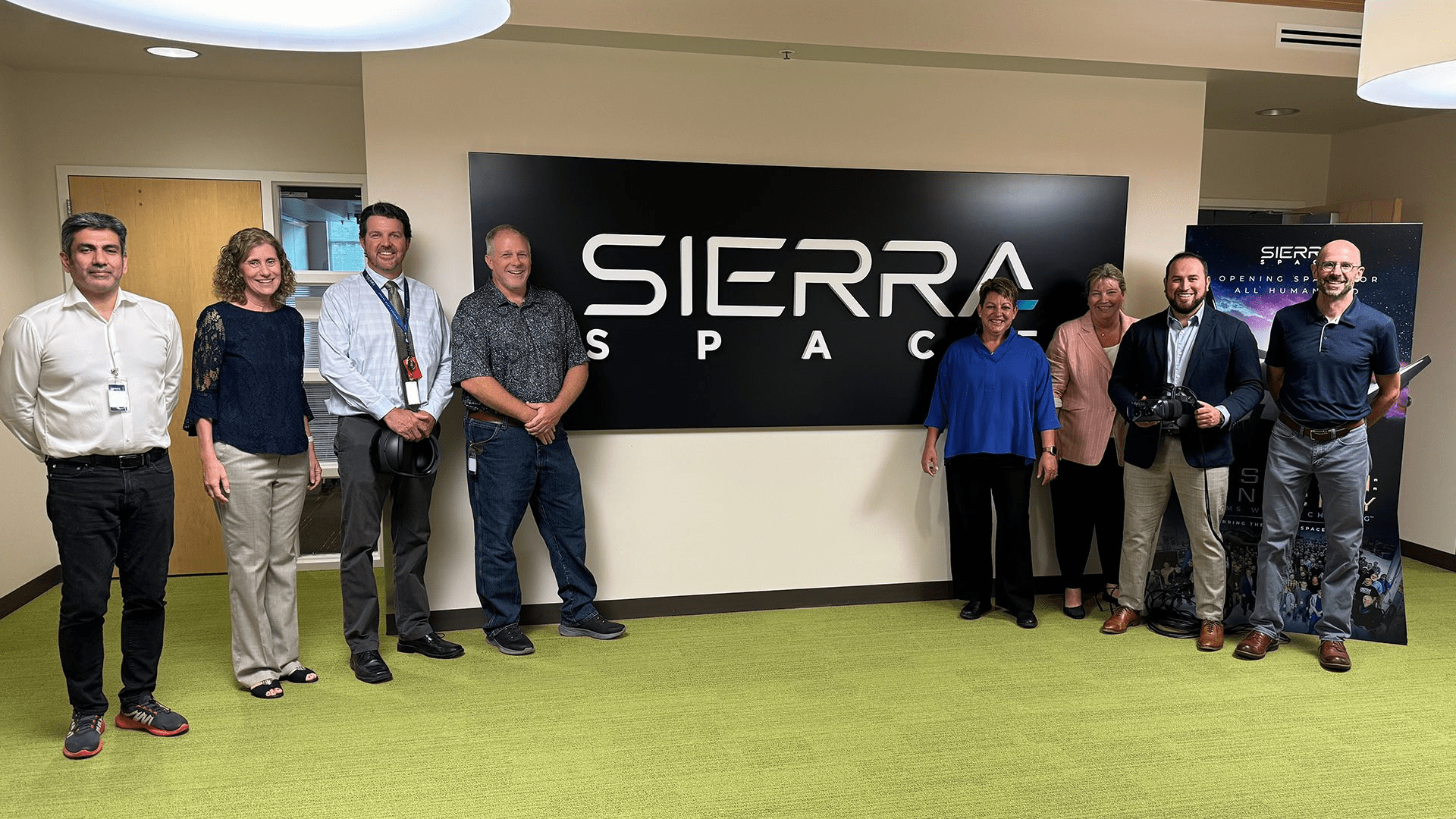

iQ3Connect, Sierra Space, and the CDLE: Immersive Techno…

Read More

News

Reimagine Workforce Training with iQ3Connect’s Rel…

Read More

XR Workspace

Augmented Reality – AGV Endplate Assembly Training…

View Details